HIGH QUALITY LASER CUTTING

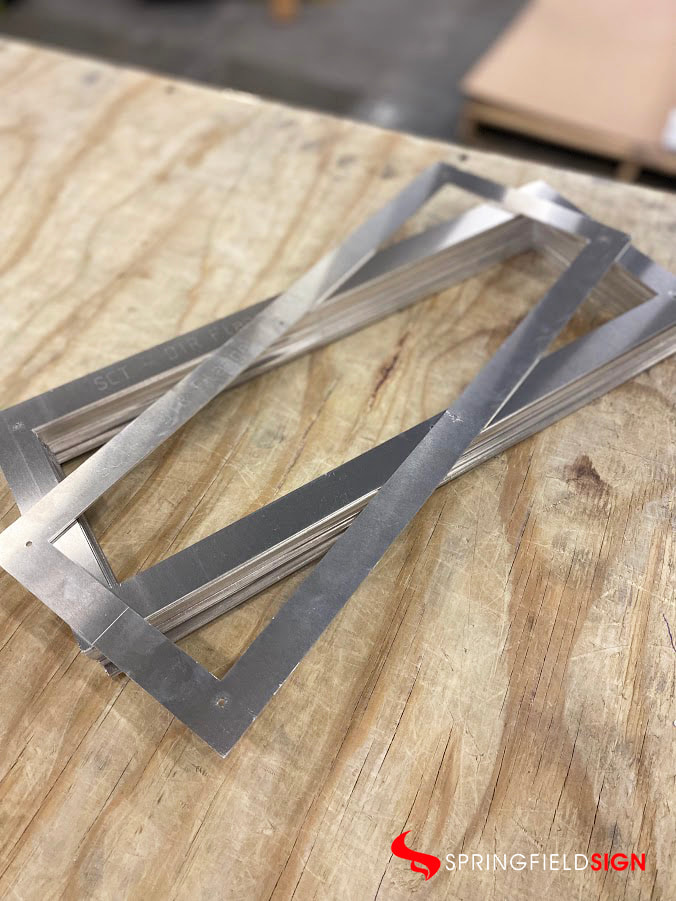

Laser cutting offers several advantages over traditional mechanical cutting: quicker production, clean cuts, fast prototyping, decreased contamination of the workpiece and small chance of operator error.

In 2021 Springfield Sign invested in a Mazak 6kW Fiber Laser and Remmert Automation System with 28 Pallet Feed System

expanding our services to offer a cost-effective solution for your manufacturing needs.

expanding our services to offer a cost-effective solution for your manufacturing needs.

6kW FIBER LASER CAPABILITIES

|

Steel laser cutting

Mild steel material thickness: 1.25 in Stainless steel material thickness: .625 in aluminum laser cutting

Maximum material thickness: 0.625 in COPPER & BRASS CUTTING

Maximum material thickness: 0.5 in SPEED

X, Y axis: 4,724 ipm QUALITY CONTROL

If an anomaly is detected during production, the operation is adjusted or paused to achieve effective cutting conditions. |

|

|

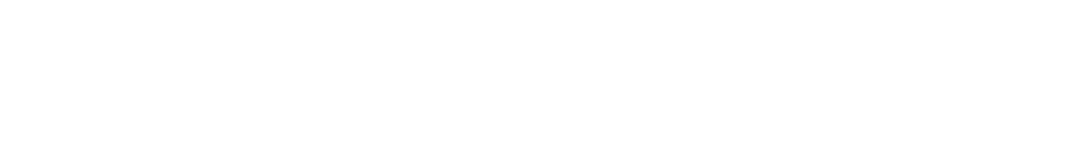

We continued our investment in automation in 2023 with the addition of the Mazak FT-150 Fiber Tube Laser.

The FT-150 FIBER has been designed for high-speed cutting and reduced non-cutting process to improve cycle times. The result is superior productivity with high throughput. This fiber tube laser machine includes a unique design and a proprietary agile U-Axis to facilitate speed and productivity. The FT-150 FIBER utilizes a series of advanced technologies and optional features to streamline and automate laser-cutting tube production processes. |

|

|

|

|

CONTACT |

LOCATION4825 E Kearney

Springfield, MO 65803 |

HOURSMon- Fri 7:00am - 5:00pm CST

|

|

Copyright © 2024, Springfield Sign & Graphics. All Rights Reserved.